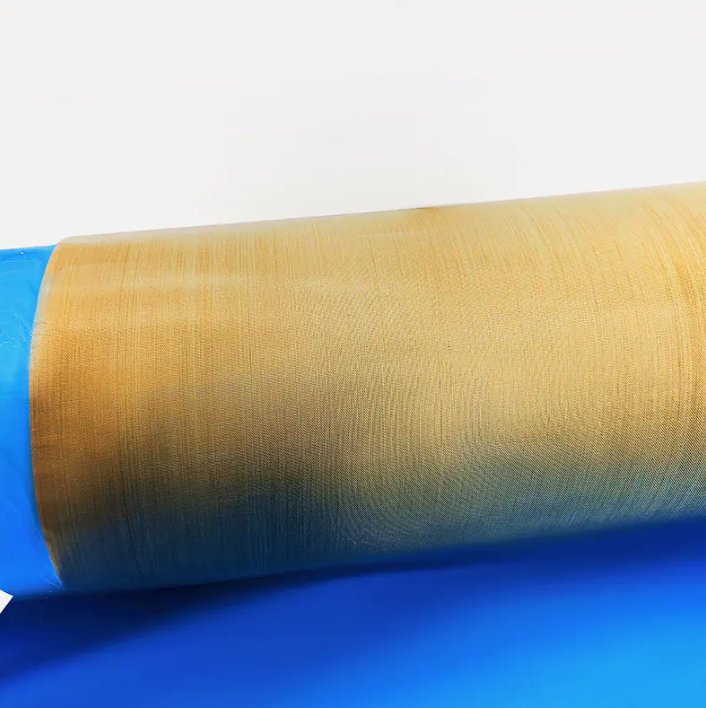

Do you know the unique bonding advantages of PTFE Tape With Acrylic Adhesive?

In modern industry and daily life, the role of sealing materials cannot be ignored. They ensure the safe and stable operation of pipelines, equipment and instruments, and prevent leakage and environmental pollution. PTFE sealing tape has become one of the most widely used sealing materials due to its excellent chemical stability and temperature resistance. However, PTFE itself has an inert surface and is difficult to form a good bond with other materials, which limits its application scenarios.

Acrylic adhesives have become an important technological breakthrough in solving the PTFE bonding problem due to their strong bonding properties and aging resistance. PTFE Tape With Acrylic Adhesive, which combines PTFE materials with acrylic adhesives, has both the corrosion resistance and high temperature resistance of PTFE and the high bonding force of acrylic adhesives, and has shown excellent sealing performance in many fields.

1. Basic analysis of PTFE materials and acrylic adhesives

1.1 Basic properties of PTFE materials

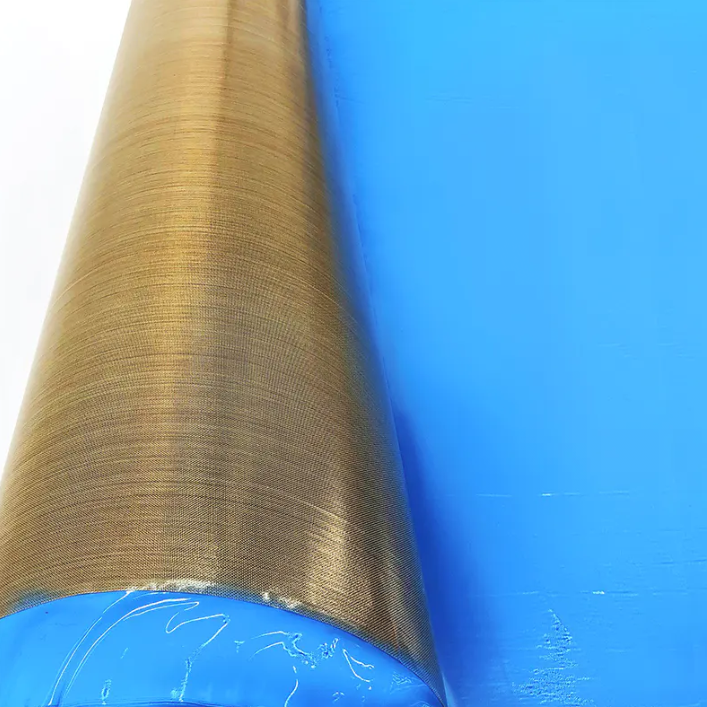

PTFE, commonly known as Teflon, is a fluorine-containing polymer with an extremely low friction coefficient and excellent chemical corrosion resistance. It can remain stable in extreme temperature ranges, usually with a temperature resistance of more than 260°C.

PTFE's molecular structure contains strong carbon-fluorine bonds, which makes it have excellent corrosion resistance and aging resistance. Whether it is strong acids, strong bases, or oils and solvents, PTFE can resist erosion. In addition, its low surface energy characteristics make its surface extremely smooth and difficult to adhere to other substances.

1.2 Characteristics of acrylic adhesives

Acrylic adhesives are synthetic polymer adhesives that have both high bonding strength and excellent weather resistance. They have good bonding effects on a variety of materials, especially in terms of temperature resistance, moisture resistance and UV resistance.

Acrylic adhesives have good elasticity and can adapt to the slight deformation and thermal expansion and contraction of the bonded materials, ensuring the long-term stability of the bonding interface. In addition, acrylic adhesives are environmentally friendly and non-toxic, meeting modern green manufacturing standards.

1.3 Technical difficulties and breakthroughs in combining the two

PTFE's inert surface is the root cause of the difficulty in bonding. Ordinary adhesives are difficult to form effective chemical or physical bonds with PTFE, and the bonding strength is low and easy to fall off.

In order to achieve efficient bonding of PTFE and acrylic adhesives, the PTFE surface needs to be modified technically, such as corona treatment, plasma treatment or chemical coating, to enhance its surface activity. At the same time, the development of specially formulated acrylic adhesives to improve its adhesion to PTFE has become the key to achieving a perfect combination of the two.

This technological breakthrough gives PTFE Tape With Acrylic Adhesive the advantages of the PTFE material itself, while achieving strong and lasting adhesion, broadening its application space.

2. Unique bonding advantages of PTFE Tape With Acrylic Adhesive

2.1 Excellent initial adhesion and lasting adhesion

PTFE Tape With Acrylic Adhesive has excellent initial adhesion, which can quickly and firmly adhere to various substrate surfaces during construction, greatly shortening the construction time. This is especially important for industrial maintenance and on-site construction.

More importantly, it exhibits long-lasting adhesion and can resist adhesion attenuation caused by environmental changes. Whether in high temperature, humidity or mechanical vibration environment, the tape can still maintain stable adhesion, ensuring the safe operation of the sealing system and reducing maintenance frequency and cost.

2.2 Excellent temperature and corrosion resistance

The tape has excellent high temperature resistance and is suitable for environments with temperatures up to 260°C or even higher, meeting the stringent requirements of multiple industries such as electricity, chemical industry, and manufacturing.

At the same time, the chemical inertness of PTFE itself combined with the corrosion resistance of acrylic adhesive enables the tape to resist the erosion of a variety of strong acids, strong alkalis and solvents. This corrosion resistance greatly extends the service life of the sealing material and reduces equipment failures caused by material failure.

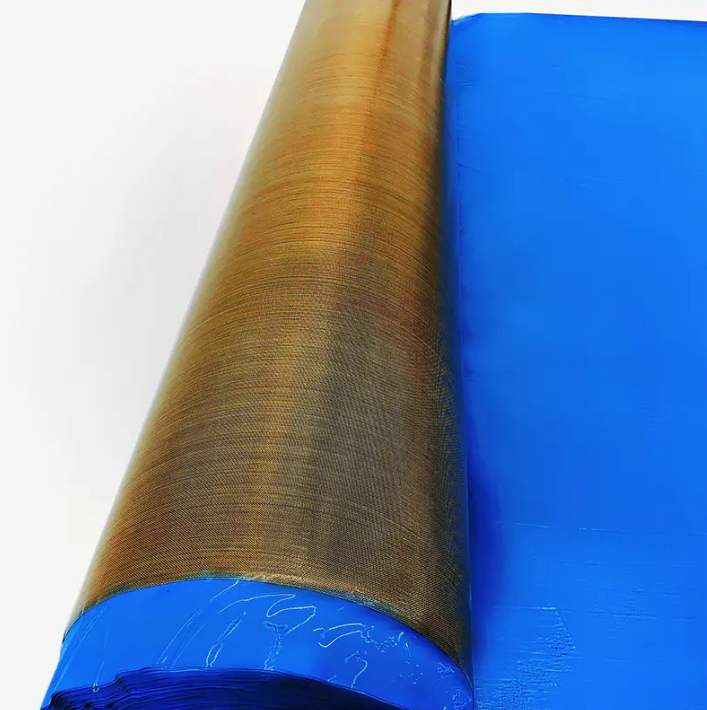

2.3 Good elasticity and flexibility

Acrylic adhesives give the tape a certain elasticity, allowing it to adapt to the slight deformation of the adhesive surface caused by temperature changes or mechanical loads. The tape will not crack or fall off due to deformation, ensuring the continuity of the seal.

This flexibility also allows the tape to fit tightly to surfaces with complex shapes, such as curved pipes and joints, to improve the overall sealing effect.

2.4 Environmentally friendly and non-toxic, in line with modern safety standards

With the improvement of industrial environmental protection standards, the environmental performance of tapes has become an important consideration. PTFE Tape With Acrylic Adhesive adopts a low-VOC formula to ensure that no harmful volatiles are released during construction and use, ensuring the safety of operators and the environment.

Its non-toxic and harmless properties make it suitable for fields with high requirements for hygiene and safety, such as food processing and medical equipment, further expanding the scope of application.

3. Application fields and actual performance

3.1 Key role in pipeline and valve sealing

The sealing of pipeline systems is a key link to prevent fluid leakage and ensure production safety. PTFE Tape With Acrylic Adhesive can effectively fill the gap between pipeline threads and prevent medium leakage.

Its high temperature pressure resistance and chemical stability ensure excellent performance in oil and gas, chemical industry, water supply and other fields, ensuring long-term safe operation of pipeline systems, reducing maintenance frequency and economic losses.

3.2 Sealing applications of electronic equipment and precision instruments

Electronic equipment has extremely high requirements for moisture-proof and dust-proof sealing. The high adhesion and good elasticity of the tape ensure that key components are firmly protected, preventing the intrusion of external moisture and dust, and extending the life of the equipment.

In addition, the high temperature resistance and non-corrosion characteristics adapt to the heat and complex environment generated during the operation of electronic products, ensuring stable performance.

3.3 Challenges and responses in the aerospace and automotive industries

The aerospace and automotive industries have extremely high requirements for material performance. The tape, with its lightweight and high-strength bonding characteristics, meets the needs of these fields for safety, durability and lightweight.

It can withstand high-frequency vibrations and extreme climates, ensure reliable sealing of key parts of aircraft and automobiles, and improve overall system safety and performance.

3.4 Innovative applications in other special fields

With the development of material technology, PTFE Tape With Acrylic Adhesive has shown unique advantages in high-standard fields such as medical devices and food processing. Its environmentally friendly, non-toxic and high adhesion meet the industry's strict hygiene and safety regulations.

Customized tape solutions help various industries achieve more efficient and safer production and maintenance, and promote technological progress.

4. Usage tips and precautions

4.1 Correct surface treatment and construction method

To ensure the best bonding effect, the adhesive surface must be thoroughly cleaned before construction to remove grease, dust and other impurities. Keeping the substrate dry and flat will help the tape form a tight bond.

During construction, it is recommended to use it under suitable temperature conditions and apply pressure evenly to ensure that the tape fits firmly. Avoid bubbles and wrinkles to ensure sealing performance.

4.2 Storage and maintenance recommendations

The tape should be stored in a dry, cool place, away from direct sunlight and high temperature environment to prevent damage to the adhesive performance. The packaging is well sealed to effectively avoid moisture and contamination.

Regularly check the appearance and adhesion of the stock tape to avoid performance degradation due to long-term storage, which will affect the subsequent use effect.

4.3 Core parameter reference when purchasing

When purchasing, users should pay attention to the thickness, width, adhesive type and temperature resistance level of the tape. Select the appropriate specifications according to the specific application environment to ensure that the sealing performance meets the use requirements.

At the same time, pay attention to the environmental indicators and chemical resistance of the tape, choose products that meet industry standards and safety specifications, and ensure safety and effectiveness.

5. Future development trends

5.1 Research and development of new adhesive formulas

Scientists and engineers continue to promote the optimization of acrylic adhesive formulas to improve their bonding ability and environmental adaptability to inert materials such as PTFE.

The tape of the future will be thinner, stronger, and have a wider range of temperature and chemical resistance to meet the personalized needs of more industrial fields.

5.2 The rise of smart materials and functionalized tapes

Smart tapes will integrate sensing technology to achieve self-repair, self-monitoring and fault warning functions, bringing revolutionary changes to industrial maintenance.

Functional materials will enable tapes to have multiple properties such as antibacterial, fireproof, and antistatic, expand application scenarios, and improve safety and reliability.

5.3 The evolution of industry standards and regulations

With the improvement of global requirements for environmental protection and safety, the standards of the tape industry are constantly improving, promoting the development of technology and products towards high quality and low environmental impact.

Standardized testing and certification systems will enhance user confidence, promote the healthy development of the industry, and achieve sustainable production and application.

Conclusion

PTFE Tape With Acrylic Adhesive is an innovative sealing material that combines the excellent performance of PTFE materials with the strong bonding advantages of acrylic adhesives. With its excellent temperature resistance, corrosion resistance, elasticity and environmental protection characteristics, it has become an important choice for sealing applications in many industrial fields.

Through scientific construction and maintenance, and reasonable selection and use, this tape can significantly improve the safety and stability of the sealing system, reduce maintenance costs, and help industrial equipment operate efficiently. Looking to the future, with the continuous innovation of technology, PTFE Tape With Acrylic Adhesive will show greater potential and value in more industries.

English

English Español

Español русский

русский