How to Choose the Right PTFE Film Tape?

Selecting the optimal PTFE film tape for your specific application is a critical decision that impacts performance, efficiency, and cost. With numerous variations available, navigating the key properties and intended uses can be challenging. This comprehensive guide will delve into the essential factors you must consider, moving beyond basic descriptions to provide a detailed framework for evaluation. We will explore core material characteristics, compare different tape constructions, and align these properties with real-world industrial demands. By understanding the nuances between various PTFE tape options, you can make an informed choice that ensures reliability, durability, and maximum value for your operational needs, whether in manufacturing, packaging, or high-temperature processing.

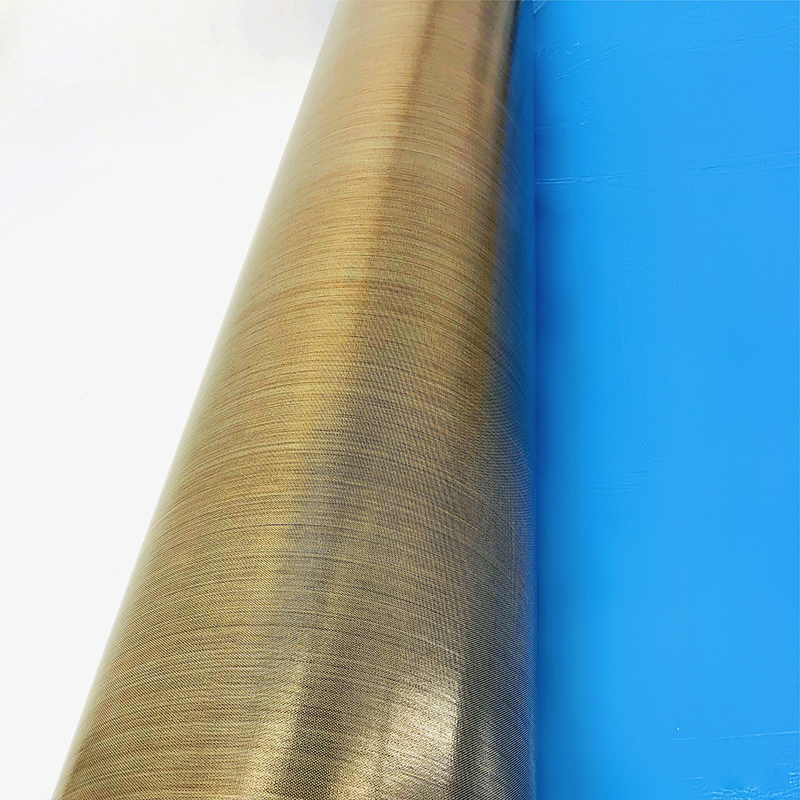

Understanding Core Material Properties and Grades

The foundation of choosing the right PTFE tape lies in a deep understanding of its inherent material properties and the different grades available. Polytetrafluoroethylene, or PTFE, is renowned for its exceptional performance characteristics, but not all PTFE tapes are created equal. Variations in manufacturing processes, purity, and reinforcement lead to products suited for vastly different environments.

Primary Characteristics Defining Performance

Several non-negotiable properties define the baseline performance of any PTFE film tape. First and foremost is its unparalleled non-stick nature, which provides a near-frictionless surface that prevents adhesion of most materials. This is complemented by an extremely wide operating temperature range, typically from -200°C to +260°C continuously, with the ability to withstand even higher short-term peaks. Furthermore, PTFE tape is chemically inert, meaning it resists attack from virtually all industrial chemicals, solvents, and acids. Its excellent dielectric strength makes it a superb electrical insulator. However, one must also consider its limitations, such as susceptibility to creep (cold flow) under sustained mechanical load and a relatively high coefficient of thermal expansion. When evaluating tapes, it is these fundamental traits that must be matched against your application's stressors.

Differentiating Between Standard, High-Purity, and Filled PTFE Tapes

Beyond the basics, PTFE tapes are categorized into different grades. Standard PTFE tape offers a balance of properties for general-purpose use. ptfe film tape for food processing conveyor belts, however, demands a high-purity, FDA-compliant or equivalent food-grade material. This grade is manufactured with stringent controls to ensure no additives or contaminants could migrate into food products. It must also withstand repeated cleaning cycles with harsh sanitizers. Conversely, for applications requiring enhanced mechanical properties, filled PTFE tapes are used. These incorporate materials like glass fiber, carbon, graphite, or bronze. These fillers significantly improve wear resistance, reduce creep, enhance thermal conductivity, and increase compressive strength. For instance, a tape filled with glass fiber is far more suitable for bearing pads or abrasive environments than a pure PTFE tape. The choice between these grades is the first critical step in the selection process.

Analyzing Tape Construction: Backing, Adhesive, and Thickness

The performance of PTFE film tape is not solely dependent on the PTFE layer itself; its construction—comprising the film backing, the adhesive system, and the overall thickness—plays an equally vital role. This multilayered structure determines how the tape interfaces with your equipment and withstands operational demands.

The Role of Film Backing and Surface Treatment

The PTFE film backing is the functional surface. Its quality, density, and surface energy are crucial. A higher-density film offers better chemical resistance and lower permeability. For applications involving release, such as in composite molding or as a non stick tape for heat sealing jaws, the surface treatment of the film is paramount. While PTFE is inherently non-stick, some tapes undergo further surface etching or corona treatment to modify the surface energy slightly, which can be beneficial for specific adhesive bonding or to achieve a consistent release force. However, for most high-temperature non-stick applications, an untreated, pristine surface is preferred to maintain the lowest possible coefficient of friction and prevent any transfer of treatment agents under heat.

Selecting the Correct Adhesive System for Your Environment

The adhesive is what bonds the tape to your substrate, and its failure means the entire product fails. The selection must be based on the substrate material (metal, plastic, rubber), surface preparation, and the operating environment.

- Acrylic Adhesives: Offer excellent environmental resistance, including to UV light, solvents, and plasticization. They have good high-temperature performance, often up to 150-180°C, and age very well. Their initial tack can be lower than silicone.

- Silicone Adhesives: Provide superior high-temperature resistance, frequently exceeding 200°C. They offer excellent initial tack and conformability, especially on slightly irregular surfaces. However, they can be more susceptible to chemical attack from solvents and have lower sheer strength.

- Rubber-Based Adhesives: Generally used for lower-temperature, high-initial-tack applications. They are not suitable for demanding industrial high-heat or chemical exposure.

For a low friction tape for sliding doors and drawers, an acrylic adhesive is often sufficient due to its good balance of strength, environmental resistance, and the moderate temperatures involved. The key is ensuring the adhesive's service temperature range fully encompasses the application's temperature, including any friction-generated heat.

Understanding Thickness and Its Impact on Function

Thickness is a critical but often misunderstood parameter. It is not merely about durability; it affects conformability, thermal transfer, and electrical insulation.

- Thin Tapes (0.03mm - 0.08mm): Highly flexible, excellent for tight radii, complex shapes, and applications where minimal space is available. They provide basic non-stick and release properties. However, they offer less wear resistance and lower dielectric strength.

- Medium Tickness Tapes (0.1mm - 0.25mm): The most common range for industrial applications. They offer a good balance of durability, conformability, and performance properties like insulation and chemical resistance.

- Thick Tapes (0.3mm and above): Used for heavy-duty applications such as gasketing, wear pads, and ptfe tape for high temperature gasketing applications. They provide excellent compressive strength, superior electrical insulation, and can be machined. Their conformability is limited.

The wrong thickness can lead to premature failure. A tape that is too thin for a gasketing application will extrude and fail under bolt pressure, while a tape that is too thick for a delicate sealing jaw may not conform properly, leaving gaps.

Matching Tape Specifications to Industrial Applications

With an understanding of properties and construction, the next step is to meticulously align these specifications with the precise demands of your application. This is where theoretical knowledge meets practical necessity, and where the consequences of a poor match become evident.

High-Temperature and Non-Stick Processing Lines

In industries like packaging, plastics, and textiles, heated elements like sealing jaws, platens, and guide rails are ubiquitous. The tape applied here must prevent melt-adhesion of substrates (like polyethylene film or hot-melt glue) and protect the equipment. For a non stick tape for heat sealing jaws, the critical parameters are:

- Continuous Temperature Rating: Must exceed the jaw's operating temperature by a safe margin (e.g., 20-30°C).

- Adhesive Performance: The adhesive must maintain its bond at that temperature without oozing, carbonizing, or losing shear strength. A high-temperature silicone or specialty acrylic is typically required.

- Surface Release: The PTFE surface must be smooth and uncontaminated to ensure consistent, clean release cycle after cycle.

- Thickness: A medium thickness (0.13mm-0.18mm) is common, providing enough durability to withstand occasional abrasion from tools or misaligned packages without being too bulky.

A failure in this application leads directly to production downtime for cleaning or tape replacement, directly impacting output and cost.

Wear Reduction and Low-Friction Guides in Machinery

Reducing friction on guide rails, sliding surfaces, and conveyor components is essential for smooth operation, energy efficiency, and reducing wear on both the component and the product being conveyed. This is where the concept of a low friction tape for sliding doors and drawers scales up to industrial machinery. Key considerations include:

- Dynamic Friction Coefficient: The lower, the better. A pure, unfilled PTFE tape typically offers the lowest coefficient.

- Wear Resistance: If the application involves significant load or continuous movement, a filled PTFE tape (e.g., with bronze or graphite) might be necessary to extend service life, even if its friction coefficient is slightly higher than pure PTFE.

- Load Bearing: The tape and its adhesive must withstand the pressure exerted by the sliding object without significant creep or deformation.

For example, applying a suitable PTFE tape to the guide rails of an automated storage system can dramatically reduce the power required for movement and eliminate the need for periodic lubrication, creating a cleaner, maintenance-friendly operation.

Chemical and Corrosive Environments

In chemical processing, plating lines, or laboratories, equipment is exposed to aggressive substances. PTFE's chemical inertness makes it ideal for protecting surfaces like tank flanges, pipe thread seals (though film tape differs from thread seal tape), and laboratory bench tops. When selecting tape for these areas, the adhesive choice becomes the weak link. An acrylic adhesive with broad chemical resistance is usually mandatory. The tape must also resist permeation, which is a function of the PTFE film's density and thickness. A thin tape might allow vapors to eventually penetrate and attack the substrate or the adhesive bond. Furthermore, in applications like ptfe film tape for food processing conveyor belts, the chemical resistance extends to cleaning agents like caustic sodas, acids, and chlorine-based sanitizers, while also maintaining food safety compliance.

Critical Selection Factors: A Detailed Comparison

To synthesize the information, making a final choice requires direct comparison across multiple axes. The following table contrasts key decision factors for two common, yet distinct, application scenarios previously discussed. This comparative analysis highlights how priorities shift based on use.

The decision between a tape suited for a heat sealing jaw versus one for a high-temperature gasket involves trade-offs. For the heat sealer, the primary interface is with a molten polymer requiring clean release; the mechanical load is relatively low but thermal cycling is constant. The adhesive's high-temperature integrity is paramount. In contrast, for a gasketing application, the tape is under constant compressive force, often between metal flanges, and must act as a seal against fluids or gases. Here, the tensile strength, creep resistance, and thickness of the PTFE film itself are more critical than the adhesive's performance, as the seal is often achieved through compression and the tape's bulk properties. Using a thin, adhesive-reliant tape for a gasket will result in extrusion and leakage, while using a thick, filled gasketing tape on a heat sealer would be expensive, poorly conforming, and unnecessary.

| Selection Factor | Non-Stick Tape for Heat Sealing Jaws | PTFE Tape for High Temperature Gasketing Applications |

|---|---|---|

| Primary Function | Release of sticky materials, surface protection. | Creating a static seal under compression, filling flange imperfections. |

| Key Performance Metric | Low surface energy (non-stick), consistent adhesive bond at high temperature. | Compressive strength, creep resistance, chemical resistance of the film. |

| Critical Material Property | Purity and smoothness of PTFE surface; high-temp adhesive. | Thickness and density of PTFE film; often uses filled PTFE for strength. |

| Typical Thickness Range | 0.08mm - 0.18mm | 0.5mm - 3.0mm (often sheets or pads, but heavy-duty tapes exist) |

| Adhesive Importance | Extremely High. The tape is only functional if it stays bonded. | Low to None. Many gaskets are non-adhesive and are clamped in place. |

| Failure Mode if Incorrect | Adhesive fails, tape lifts, product sticks to jaw causing downtime. | Tape extrudes or compresses excessively, leading to leaks and seal failure. |

Implementation and Long-Term Performance Considerations

Choosing the right tape is only half the battle; proper implementation and an understanding of its lifecycle are essential to realizing its full value. Even the best-performing tape will underperform if installed incorrectly or monitored inadequately.

Surface Preparation and Installation Best Practices

The bond is only as good as the surface it adheres to. Proper installation is non-negotiable for adhesive-backed tapes. The substrate must be clean, dry, and free of oil, grease, dust, rust, and old adhesive residue. Solvent cleaning followed by abrasion (e.g., light sanding) for metals often provides the best surface profile. The application temperature should ideally be between 15°C and 35°C. During installation, firm, even pressure should be applied using a roller or squeegee to eliminate air bubbles and ensure full adhesive contact. For overlapping seams on conveyor belts or large surfaces, the overlap direction should be considered relative to the direction of product travel or wear to prevent edges from catching and lifting. For non-adhesive applications like gasketing, ensuring the flange surfaces are flat, clean, and that the bolt load is even and torqued to specification is critical to prevent localized over-compression and failure.

Monitoring Wear, Maintenance, and Replacement Cycles

PTFE tape is a consumable product with a finite service life. Establishing a preventive maintenance schedule to inspect tape condition prevents catastrophic failure. Key signs of wear or impending failure include:

- Edge Lift or Curling: Indicates adhesive breakdown or contamination during installation.

- Discoloration or Burnishing: On a non stick tape for heat sealing jaws, this may be normal polymer transfer, but excessive buildup or a change in texture indicates the tape surface is degrading.

- Cuts, Scratches, or Deep Grooves: Physical damage from sharp objects or abrasive materials. This is common on conveyor systems and directly compromises the tape's function as a ptfe film tape for food processing conveyor belts by creating pockets for bacterial growth or snag points.

- Loss of Surface Slickness: The tape no longer provides the intended low-friction or release properties, increasing drag or causing sticking.

- Visible Extrusion or Thinning: In gasketing applications, this is a clear sign the material has reached its creep limit and the seal integrity is compromised.

Documenting the lifespan of the tape under specific conditions allows for proactive replacement, minimizing unplanned downtime. By understanding the failure modes and implementing a rigorous selection and maintenance protocol, you transform PTFE film tape from a simple commodity into a reliable, high-performance component of your operational success.

English

English Español

Español русский

русский