Selecting PTFE Film: Applications, Properties and Industry Use Cases

Understanding PTFE Film and Its Unique Material Characteristics

PTFE Film (Polytetrafluoroethylene film) is a high-performance thin film material made from PTFE resin, well known for its outstanding chemical resistance, temperature tolerance, and electrical insulation properties. Due to the presence of strong carbon-fluorine bonds in its molecular chain structure, PTFE Film possesses exceptional stability, maintaining its performance in most harsh industrial environments.

1. Main Physical and Chemical Properties

| Property | Typical Range | Description |

|---|---|---|

| Service Temperature Range | -200°C ~ +260°C | Can withstand extreme high and low temperatures for long periods |

| Melting Point | Around 327°C | Maintains dimensional stability even at high temperatures |

| Dielectric Constant (1 MHz) | 2.0–2.1 | Excellent electrical insulation |

| Volume Resistivity | ≥1017 Ω·cm | Extremely high insulation to prevent leakage |

| Tensile Strength | 20–35 MPa | Balanced flexibility and strength |

| Elongation at Break | 200%–400% | Good ductility, easy to process |

| Friction Coefficient | 0.05–0.1 | Strong self-lubrication, reducing mechanical wear |

| Water Absorption | <0.01% | Virtually non-hygroscopic, suitable for humid environments |

| Chemical Resistance | Inert to almost all chemicals | Including acids, alkalis, and solvents |

2. Performance Advantages

Extreme Temperature Resistance

PTFE Film can operate stably at temperatures as low as -200°C and as high as 260°C, making it valuable in aerospace, chemical, and electronics industries.

Chemical Inertness

Due to the high stability of the carbon-fluorine bond, PTFE Film resists almost all corrosive chemicals (including strong acids and alkalis), making it ideal for chemical processing equipment and sealing gaskets.

Excellent Electrical Insulation

Low dielectric constant and extremely high volume resistivity make PTFE Film ideal for high-frequency electronics and insulation films.

Low Friction Coefficient

With a friction coefficient close to ice, PTFE Film reduces mechanical wear and extends equipment lifespan.

Water and Moisture Resistance

Almost zero water absorption allows PTFE Film to maintain stable performance in high-humidity or underwater environments.

Manufacturing Processes and Quality Standards for PTFE Film

The manufacturing process of PTFE Film directly impacts its physical properties, dimensional accuracy, and service life. To meet diverse industrial requirements, manufacturers select suitable forming and processing techniques based on application needs and adhere to strict quality standards to ensure product consistency and reliability.

1. Common Manufacturing Processes

Mold Sintering and Skiving

Process: PTFE powder → Cold press forming → High-temperature sintering → Skiving into thin films

Features: Can produce ultra-thin films (thickness as low as 0.01 mm), smooth surface, ideal for electrical insulation and sealing.

Extrusion Molding

Process: PTFE blend → Extrusion → Drying → Sintering → Film winding

Features: Suitable for continuous large-roll production, high thickness uniformity, ideal for mass industrial use.

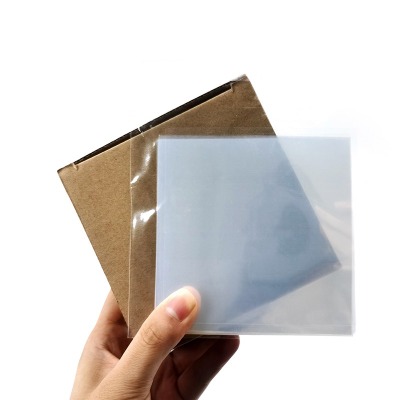

Casting

Process: PTFE dispersion → Uniform coating → Drying and curing → Peeling into film

Features: Can produce transparent or semi-transparent PTFE Film, precise thickness control, suitable for optical and chemical detection applications.

2. Process Parameter Comparison

| Process Type | Thickness Range | Surface Smoothness | Dimensional Accuracy | Typical Applications |

|---|---|---|---|---|

| Mold Sintering + Skiving | 0.01–5 mm | High | High | Electrical insulation, gaskets, chemical liners |

| Extrusion Molding | 0.05–3 mm | Medium | Medium-High | Industrial coating rolls, large-scale production |

| Casting | 0.005–1 mm | High | High | Optical films, medical devices |

3. Quality Standards and Inspection Requirements

| Test Item | Purpose | Typical Acceptable Range |

|---|---|---|

| Thickness Deviation | Ensure thickness uniformity | Within ±5% |

| Tensile Strength | Assess mechanical performance | ≥20 MPa |

| Elongation at Break | Test ductility | 200%–400% |

| Dielectric Constant | Ensure insulation performance | 2.0–2.1 |

| Water Absorption | Ensure moisture resistance | <0.01% |

| Visual Inspection | Detect surface defects | No bubbles, cracks, or impurities |

4. Quality Control Focus Points

Raw Material Purity: High-purity PTFE resin enhances chemical resistance and dielectric performance.

Sintering Temperature Control: Improper temperatures can alter crystal structure, affecting strength and stability.

Processing Precision: Especially for ultra-thin films, skiving accuracy and cutting tolerances must be strictly managed.

Deep Dive: Applications and Selection Guide for PTFE Film in Key Sectors

1. Key Industry Applications

Electronics and Electrical: Used for insulation layers in cables, capacitors, and high-frequency circuit boards.

Chemical Processing: Lining and sealing materials for pipes, valves, and storage tanks resistant to corrosion.

Medical Field: Medical catheter liners, filter membranes, and biocompatible sealing materials.

Aerospace: Lightweight insulation materials, aerodynamic surface films, and sealing gaskets.

Food Industry: Non-stick conveyor belts, baking sheets, and packaging films.

2. Selection Guide

| Application Environment | Recommended PTFE Film Type | Key Parameters |

|---|---|---|

| High Temperature + Chemical Corrosion | Skived PTFE Film | Thick film, tensile strength ≥25 MPa |

| High Frequency Electrical | Cast PTFE Film | Dielectric constant 2.0–2.1, uniform thickness |

| Food Contact | PTFE Film meeting food-grade standards | Non-toxic, high temperature resistant |

| Optical or Precision Detection | Transparent PTFE Film | Light transmittance ≥90% |

Future Trends and Innovations in PTFE Film Technology

The future of PTFE Film technology is being shaped by advances in material science, precision manufacturing, and application diversification. Companies like Taizhou Yaxing Plastic Industry Co., Ltd. are at the forefront of these developments, leveraging decades of expertise and cutting-edge equipment to push the boundaries of PTFE applications.

1. Material Modification and Composite Technology

By introducing nanoparticles, fillers, or blending with other fluoropolymers, PTFE film can be tailored for enhanced wear resistance, conductivity, or optical properties. Modified PTFE composites are expected to enter more demanding sectors such as advanced medical devices and next-generation electronics.

2. Ultra-Wide and Ultra-High Precision Films

Taizhou Yaxing Plastic Industry Co., Ltd. has independently developed ultra-wide and ultra-high precision PTFE films, addressing the need for large-format applications such as architectural membranes and industrial processing lines.

3. Permanent Architectural Membranes

New generations of PTFE-based architectural membranes offer improved UV stability, tensile strength, and longevity, enabling energy-efficient, aesthetically appealing building designs.

4. Automation and Intelligent Manufacturing

The integration of German high-precision PTFE film cutting equipment and wide-width rapier looms at Taizhou Yaxing Plastic Industry Co., Ltd. exemplifies the move towards highly automated, precision-controlled production lines, reducing defects and increasing throughput.

5. Sustainability and Recycling

While PTFE is traditionally challenging to recycle, research is focusing on energy-efficient reprocessing and the development of eco-friendly alternatives without compromising performance.

6. Global Market Expansion

With self-operated import and export rights, Taizhou Yaxing Plastic Industry Co., Ltd. continues to expand its reach to Europe, America, Asia, and Africa, meeting the growing global demand for high-performance PTFE films across multiple sectors.

English

English Español

Español русский

русский